AKF Check Valve Stainless Steel 6000psi BSPT NPT For Gas

Check Valve Stainless Steel 6000psi BSPT NPT For Gas

Features of Air Compressor Check Valve

| 1 | Inline check valve stops reversed flow in orde to protect instrumentation |

| 2 | Body material in stainless steel SS316/316L cold drawn bar |

| 3 | Max.allowed working pressure 3000psi (206bar) |

| 4 | With viton O-ring |

| 5 | 100% factory tested |

Product Parameter of Check Valve Stainless Steel 6000psi BSPT NPT For Gas

Material of Construction

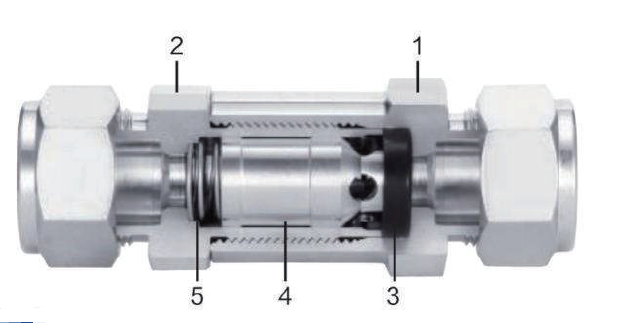

| item | part description | Qty | material |

| 1 | inlet body | 1 | SS316/316L |

| 2 | outlet body | 1 | SS316/316L |

| 3 | seal ring | 1 | Fluororubber |

| 4 | poppet | 1 | SS316/316L |

| 5 | spring | 1 | SS304 |

| nominal cracking pressure | nominal cracking pressure |

| 1 | 401 |

| 10 | 7-15 |

| 25 | 20-30 |

Ordering Information

| C- | CV- | S6- | 04 | A- | 1# | |

| Classification | Prouduct Name | Material | Size(Fractional) | Size(Metric) | Connection Type | Cracking Pressure |

| Valve | check valve | S6:SS316 | 02:1/8″ | 6:6mm | A:AFK tube end | 1#:1PSIG |

| S6L:SS316L | 04:1/4″ | 8:8mm | MR:male BSPT thread | 10#:10PSIG | ||

| 06:3/8″ | 10:10mm | FR:female BSPT thread | 25#:25PSIG | |||

| 08:1/2″ | 12:12mm | MN:male NPT thread | ||||

| 12:3/4″ | FN:female NPT thread | |||||

| 16:1″ | ||||||

Five tests for high purity gas pipelines

The purpose of the pressure test is to ensure the safety of all personnel by ensuring that the pipeline does not leak at the point of articulation after it has been subjected to high pressure. In addition, the high pressure in the pipeline can detect the presence of sand holes in the weld channel (sand holes can cause leakage due to excessive pressure).

2. The purpose of the pressure-hold test is to ensure that there are no visible leaks in the pipeline delivery system so that a helium leak test can be carried out on the pipeline system.

3. Helium Mass Spectrometry Leak Detection Purpose: To detect leaks by using a helium mass spectrometer to sense minute amounts of helium leaking into the system and to determine the size of the leak based on the amount of helium detected.

4. Particle detection, oxygen and moisture.

(1) Particle detection is the detection of the size and number of microparticles in the pipeline. If there are too many particles in the pipe, it will have a great impact on the yield of the product.

(2) The purpose of oxygen testing is to prevent chemical reactions from occurring when the oxygen content in the pipe is too high, which can affect the process.

(3) The purpose of moisture testing is to prevent chemical reactions from occurring if the water content in the pipeline is too high, which could affect the process.

A. Yes, we are manufacturer.

A.3-5days. 7-10 days for 100pcs

A.You can order it from Alibaba directly or send us a inquiry. We will reply you within 24 hours

A. We have CE certificate.

A. aluminium alloy and chrome plated brass are available. The picture shown is chrome plated brass. If you need other material, pls contact us.

A.3000psi (about 206bar)

A. Pls check cylinder type and confirm it. Normally, it is CGA5/8 male for Chinese cylinder. Other cylidner adapter are also available e.g CGA540, CGA870 etc.

A. Down way and side way. (you can choose it)

A: The free warranty is one year from the day of Commissioning qualified.If there is any fault for our products within the free warranty period, we will repair it and change the fault assembly for free.