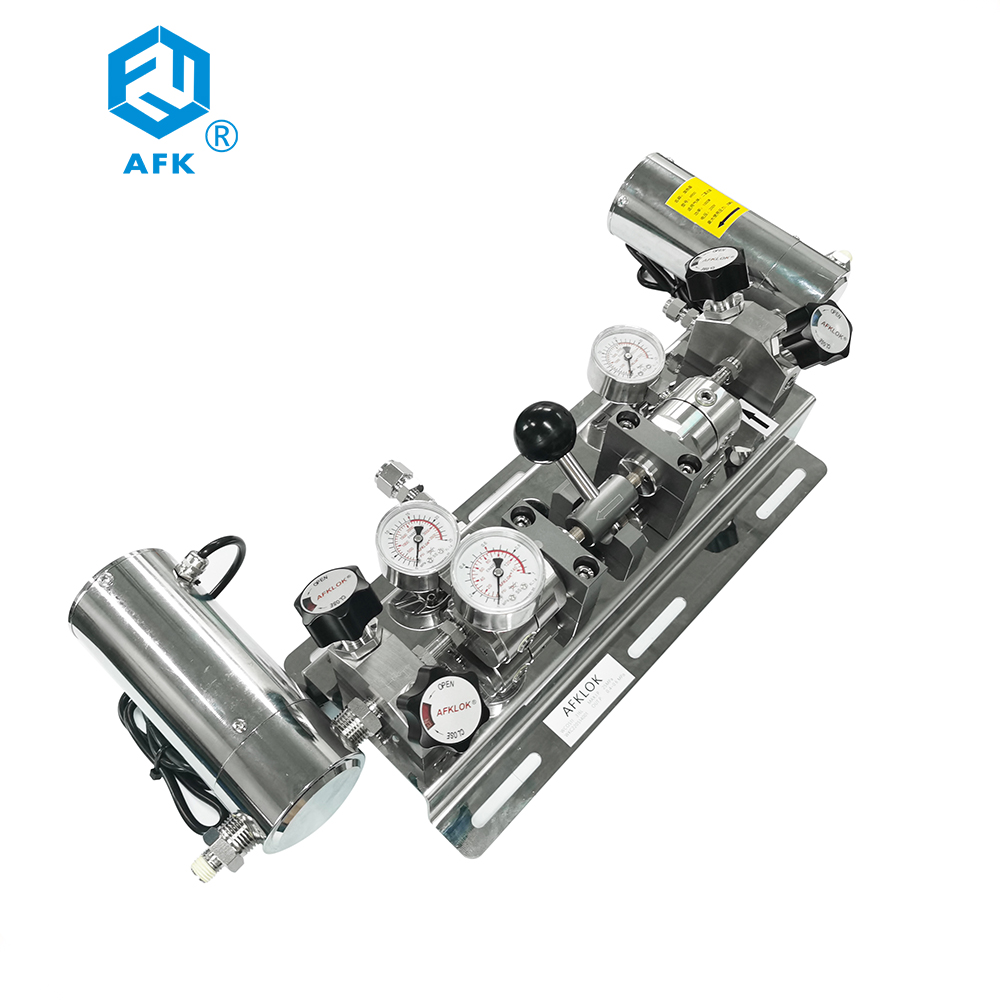

AFK Stainless Steel Double Side Gas Supply Automatic Switching Heating Device Pressure Reducing Valve

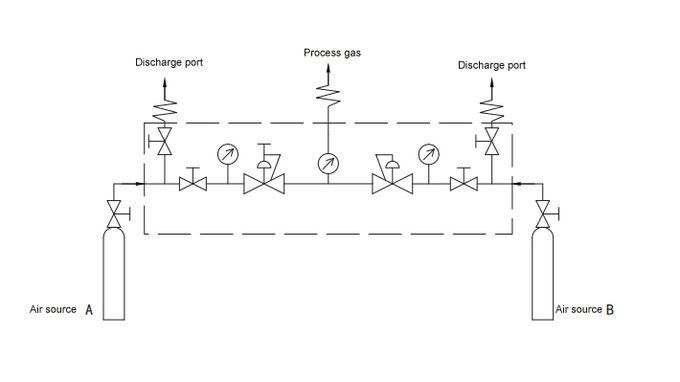

Working Principle

1. Wcosr11 series switching device includes two independent pressure reducing valves. Adjust the outlet pressure on the left and right sides by operating the linkage lever, that is, when the left increases, the right decreases and the left supplies air; When the right increases, the left decreases, and the right supplies air

2. When one side of the air supply is exhausted, it will automatically switch to the other side of the air supply

3. Close the inlet diaphragm valve, open the pressure relief diaphragm valve, empty the air source on the exhausted side, and then replace with a new air source

4. The priority air supply source can be selected by turning the switch handle

Features

- Suitable for uninterrupted air supply, automatically switches to the other end when one end is exhausted

- With priority selection handle, priority supply source can be set using the WR11 pressure reducing valve as a prototype valve, which can be used for corrosive and toxic gases

- WV4C diaphragm valve two-way three-way valve is used as a prototype valve, with fewer links

- 20 micron filter element installed at the inlet

- Oxygen environment application options are available

- Output pressure within a range, factory set

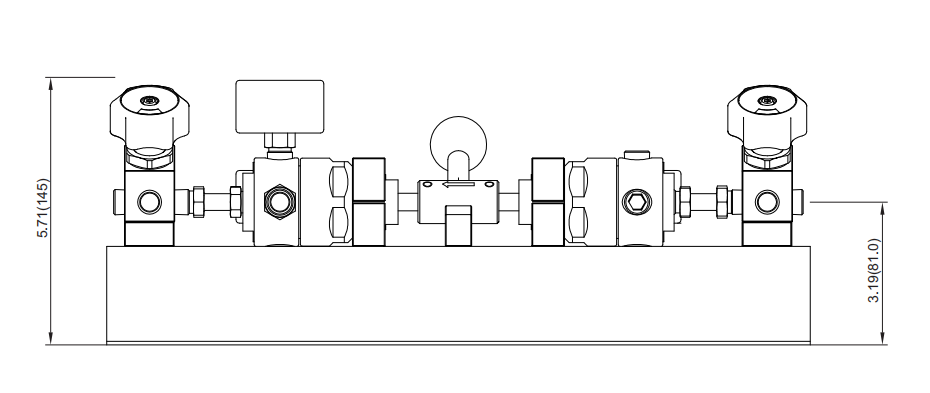

Technical Data

- Maximum inlet pressure: 3500psig

- Outlet pressure range: 85 to 115, 135 to 165, 185 to 215, 235 to 265

- Internal component materials:

- Valve seat: PCTFE

- Diaphragm: Hastelloy

- Filter element: 316L

- Operating temperature: -40℃~+74℃(-40℉~+165℉)

- Leakage rate (helium):

- Inside the valve: ≤1×10-7 mbar l/s

- Outside the valve: ≤1×10-9 mbar l/s

- Connection: No visible bubbles

- Flow coefficient (Cv):

- Pressure reducing valve: Cv=0.2

- Diaphragm valve: Cv=0.17

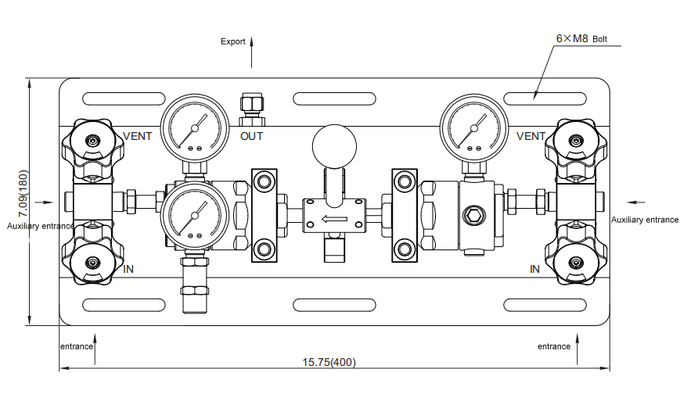

- Female ports:

- Inlet: 1/4NPT

- Outlet: 1/4NPT

- Pressure gauge port: 1/4NPT

Model selection table

| 6L | 35 | 100 | 00 10 | RC | O2 |

| body material | Inlet pressure P1 | Outlet pressure range P2 | Inlet / outlet specifications | Accessory options | Cleaning process |

| 6L SS316L | 35:3500PSI | 100:85-115PSIG | 00:1/4″NPT F | No requirement | Standard (grade BA) |

| 150:135-165PSIG | 01:1/4″NPT M | P:Inlet equipped with pressure sensor | C2:Oxygen cleaning | ||

| 200:185-215PSIG | 10:1/4″ OD | R:Outlet equipped with unloading valve | |||

| 250:235-265PSIG | 11:3/8″ OD | C:Inlet equipped with one-way valve | |||

| HC:CGANo. with high pressure hose (USA) | |||||

| HDIN:DIN No. with high pressure hose (Germany) |

Specialty Gases include rare gases, extremely pure gases and gases of the highest mixing accuracy, which are used in very demanding applications by a wide range of industries.

Many Customers have specific requirements that are not always standard mixtures. For these applications, we are able to provide the Quality Control Solution via our range of NovaCHROM Gas Chromatographs or Gas Analysers depending on the exact requirement.

There are more than 30 kinds of special gases commonly used in the electronics industry, which can be classified into non-flammable gases, combustible gases, oxidizing gases, corrosive gases, toxic gases, etc. according to the nature of danger. They can be divided into compressed gas, liquefied gas and cryogenic gas according to their physical forms.

Q. Are you manufacturer?

A. Yes, we are manufacturer.

Q.What is lead time?

A.3-5days. 7-10 days for 100pcs

Q. How do I order?

A.You can order it from Alibaba directly or send us a inquiry. We will reply you within 24 hours

Q. Do you have any certificates?

A. We have CE certificate.

Q. What materials do you have?

A. aluminium alloy and chrome plated brass are available. The picture shown is chrome plated brass. If you need other material, pls contact us.

Q. What is maximum inlet pressure?

A.3000psi (about 206bar)

Q. How do I confirm inlet connnection for cylidner?

A. Pls check cylinder type and confirm it. Normally, it is CGA5/8 male for Chinese cylinder. Other cylidner adapter are also

available e.g CGA540, CGA870 etc.

Q. How many types for connecting cylinder?

A. Down way and side way. (you can choose it)

Q. What is product warranty?

A: The free warranty is one year from the day of Commissioning qualified.If there is any fault for our products within the free warranty period, we will repair it and change the fault assembly for free.