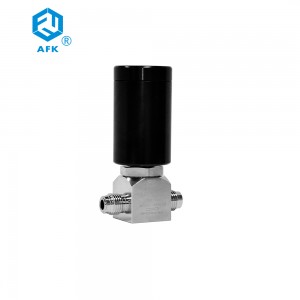

AFK 316 Stainless Steel High Pressure 1/4in Vacuum Application Pneumatic Operated Seal Diaphragm Control Valves 150psi

Pneumatic Diaphragm Valve

Features of Pneumatic Diaphragm Valve

Cleaning process

standard(WK-BA)

All welded joints shall be cleaned according to the company's standard cleaning and packaging specifications.When ordering, there is no need to add suffix

Oxygen cleaning(WK-O2)

Product cleaning and packaging specifications for oxygen environment can be provided. This product meets the requirements of astmg93c cleanliness. When ordering, please add - O2 after the order number

Specification of 316 Stainless Steel High Pressure 1/4in Vacuum Application Manual Operated Seal Diaphragm Control Valves 150psi

|

WV4H |

|||||||

|

6L |

TW |

4 |

MR4 |

Executive type |

Cleaning process |

||

|

body material |

TW:inch tube SWL Joint |

4:1/4″ |

Outlet type |

Outlet size |

handle |

Standard (grade BA) |

|

|

6L:316L SS |

MR:Male thread MCR joint |

Same as entrance |

C:Pneumatic normally closed |

O2:Oxygen cleaning |

|||

|

6LV:316L VAR |

FR: Female thread MCR joint |

O:Pneumatic normally open |

EP:Ultra high purity (EP grade) |

||||

|

6LW:316L VIM-VAR |

TF:inch OD joint |

||||||

|

FNS:NPT Female |

|||||||

| Flow data:Air@ 21℃(70℉) Water@16℃(60℉) | |||

|

1 |

pressure drop of maximum air pressure bar(psig) |

air(I/min) |

water(I/min) |

|

2 |

0.68(10) |

64 |

2.4 |

|

3 |

3.4(50) |

170 |

5.4 |

|

4 |

6.8(100) |

300 |

7.6 |

|

basic order number |

port type and size |

size in.(mm) | |||

|

A |

B |

C |

L |

||

|

WV4H-6L-TW4- |

1/4″-Tube-w |

0.44(11.2) |

0.3(7.6) |

1.12(28.6) |

1.81(45.9) |

|

WV4H-6L-FR4- |

1/4″-FA-MCR |

0.44(11.2) |

0.86(21.8) |

1.12(28.6) |

2.85(72.3) |

|

WV4H-6L-MR4- |

1/4″-MA-MCR1/4 |

0.44(11.2) |

0.58(14.9) |

1.12(28.6) |

2.24(57.0) |

|

WV4H-6L-TF4- |

OD |

0.44(11.2) |

0.70(17.9) |

1.12(28.6) |

2.54(64.4) |

Q1. What about the lead time?

A:Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than

Q2. Do you have any MOQ limit ?

A: Low MOQ 1 pic

Q3. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 5-7 days. Airline and sea shipping also optional.

Q4. How to proceed an order ?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q4. How to proceed an order ?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.